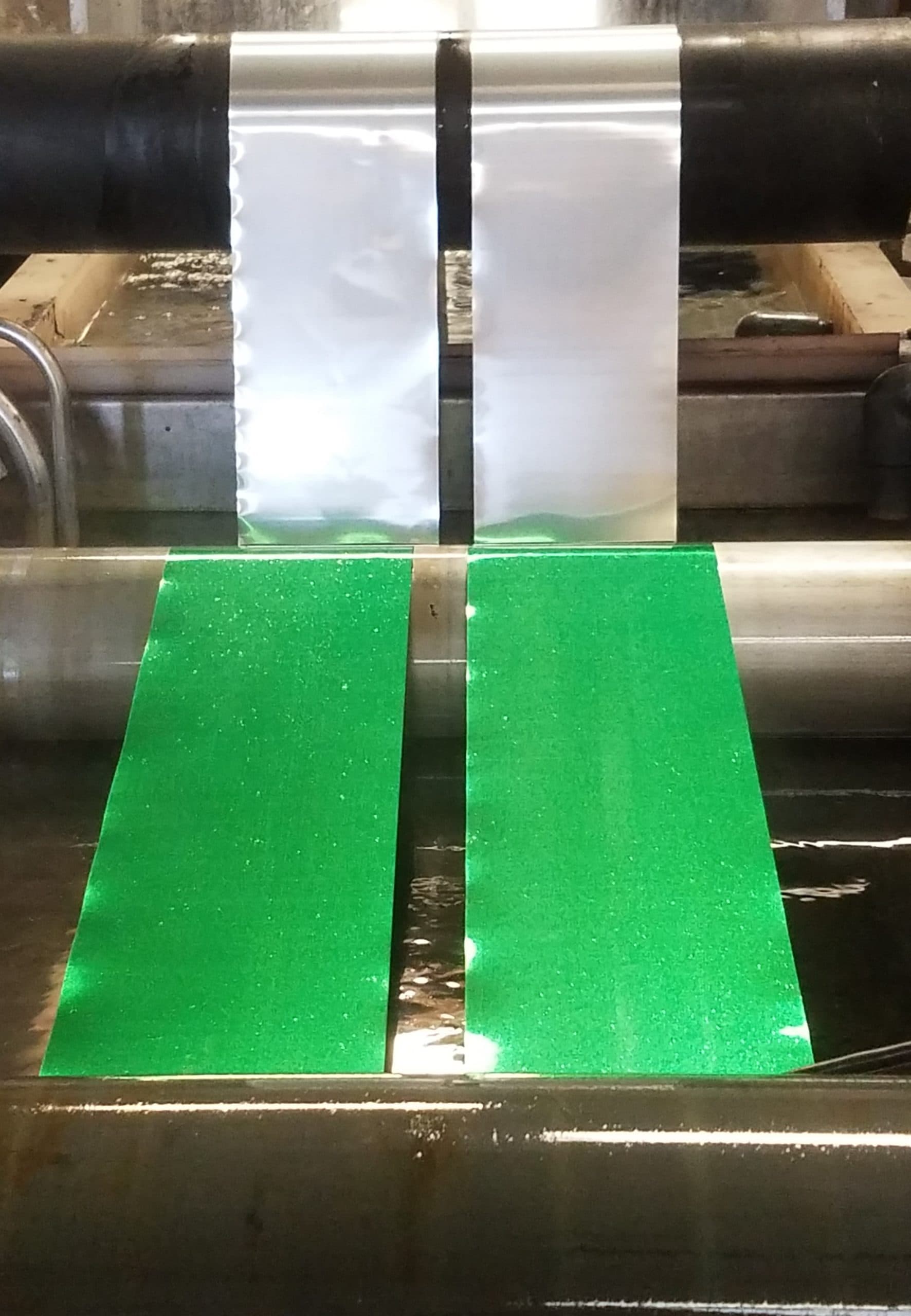

Ano-Mag’s pre-production capabilities in continuous coil coatings will eliminate the need for a dedicated vendor to outsource the conversion. As with most OEM parts and pieces of significant quantity the need to manufacture the part and then outsource the “conversion” through a dedicated vendor can be eliminated by Ano-Mag and the pre-production capabilities in coil conversion coatings.

Aerospace, stamping, roll-forming, direct die punch, identification marking, adhesive applications and dedicated small system output’s benefit from the repetitive and single source solutions no other company can offer. With a range of chemical immersion finishes and tank configurations suitable for a small batch run to filling a government contract, Ano-Mag is positioned to offer any source sided requirement with JIT delivery and repetitive service order after order.

Ano-Mag can create a single point of service, eliminating the usual collective of vendors that may specialize in one but not all areas of conversion.

In Line Services

- Slitting of Coil .00075″ to .125″

- Edge conditioning/Burr removal

- Pre-Clean oil removal and degrease

- Etch and hydroxide wash

- Anodizing (TYII/TYIII) CL 1 & 2

- Chemical Film (ChemFilm) Gold & Clear

- Surface Prep and adhesive base formation