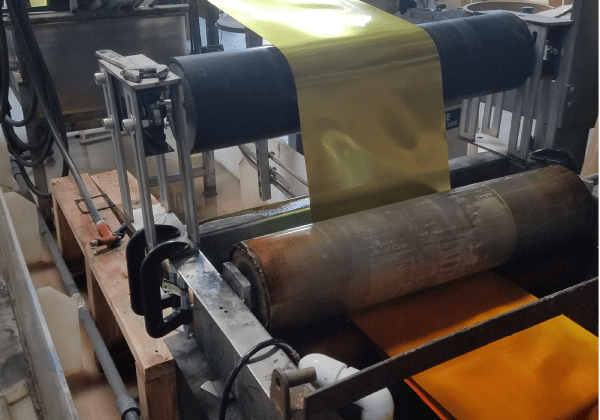

Over 20 years of service at Ano-Mag, we’ve performed continuous coil/foil chemical film applications for series 1100-7000 Aluminum alloys. We work with coil dimensions ranging from .0015in. to .050in. thickness and .125in. to 24in. width. Our chemical film bath, deionization rinse, and heat curing systems give us a unique ability to work with material dimensions that typically cannot be performed using conventional methods.

Primarily used for the pre-painted or laminated coil manufacturing industries, our process includes chemical films for aluminum alloys and single stage continuous coil lengths. We offer color applications for protection, in Chem-Film Gold and Clear, using a smooth and continuous coil process without void of coating. All chemical film processes are performed to exact customer specifications, including MIL-C-5541 upon request.

We’ve served clients worldwide with continuous coil chemical film applications using aluminum alloys. Our veteran team can work with volumes up to 1,000,000lb. within a 2-to-4 week lead time. To learn more about our chemical films for aluminum alloy coils, please review the table below, or contact us directly.