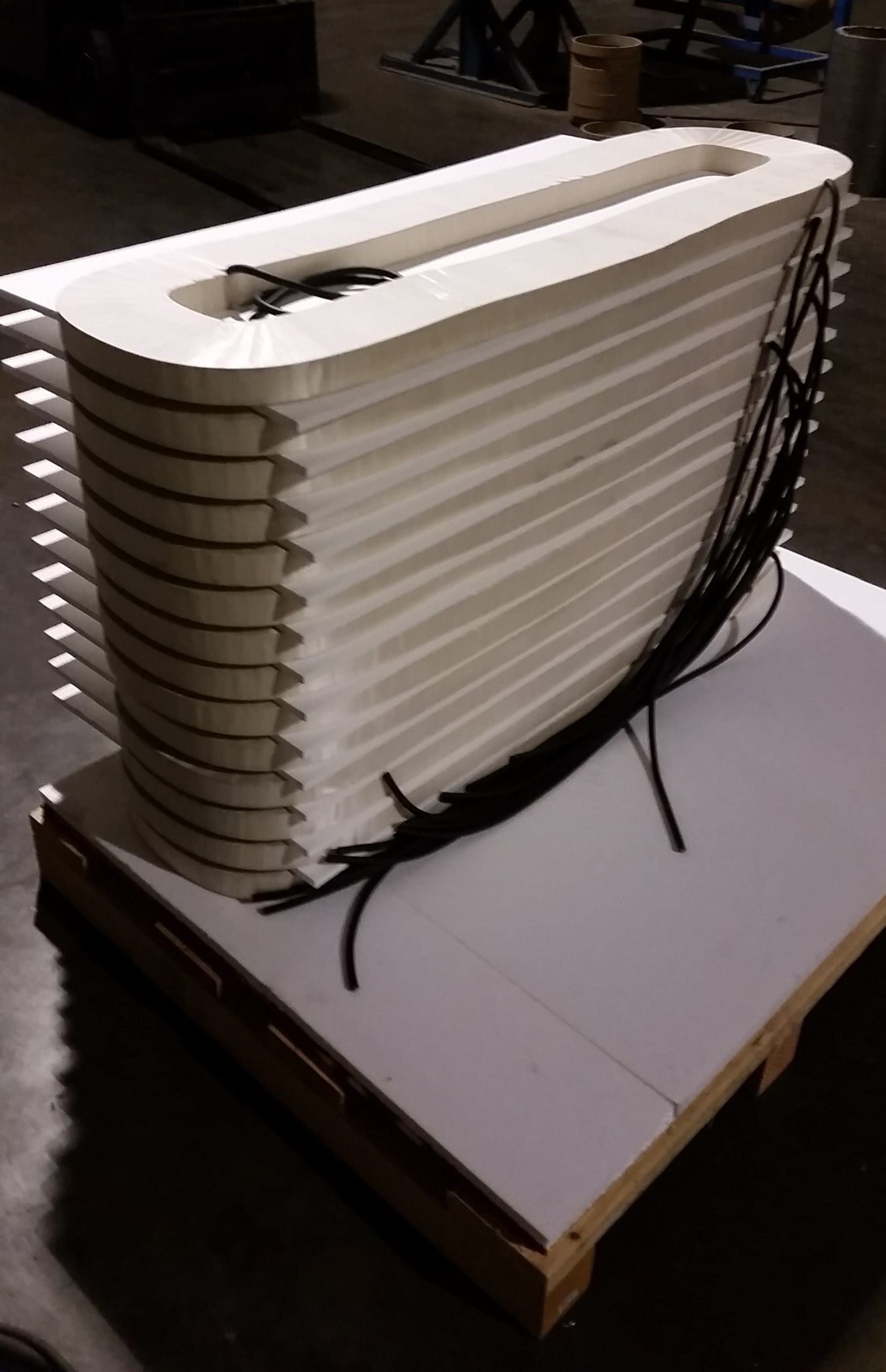

As a leader in anodized strip coil manufacturing, our team at Ano-Mag offers complete winding and lead connection of magnetic coil prior to customer installation. We can wind anodized magnetic strip to exact customer requirements in inner diameter, outer diameter, length, weight, and resistance. All finished coils include leads that are fully taped and secured, including coil surfaces, and then banded with straps for additional security. Our process uses a custom built, electronically controlled, automated tensioning and winding system that distributes equal tension across the full course of wound coil. This procedure, along with our banding and finishing services, will eliminate coil processing upon arrival at a customer’s shop so that it is prepped and ready according to their requirements.

Since 2002 we have been performing coil winding and finishing services for lifting and separating magnetic systems. Our system is capable of handling EC Grade 1350 Aluminum with dimensions between .0015 in to .050 in thick and coil widths between 1 in to 9 in at a measured resistance of ±5 % ohms. All coils are mill finished and fully anodized prior to winding and banding, with an insulation inspection process that includes Ohms metering checks per length and weight. Our coils undergo high heat application processes to improve thermal stability, current flow, and as a preventative measure for breakdown or shorts during the lifecycle of the coil. To learn more about our magnet winding and finishing services, please contact us directly or refer to the table below.