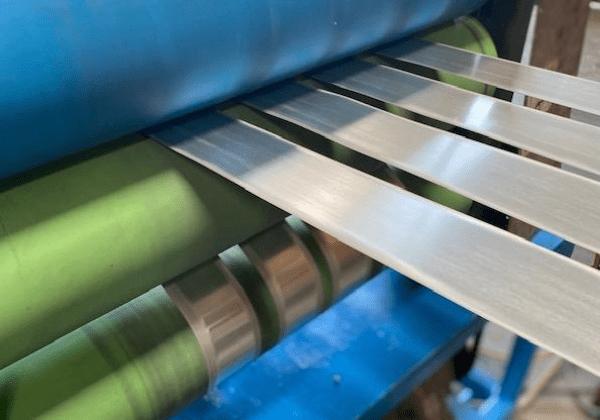

With our expertise in continuous coil processing, Ano-Mag provides anodized aluminum and custom wound magnets that exhibit an exceptional caliber of quality. Our process improves the aluminum surface, making it more corrosion resistant, abrasion resistant, harder, and more attractive. We utilize an in-line anodizing system that incorporates pre-treatment cleaning, a sulfuric acid anodizing bath, and post-treatment dye immersion, sealing, and rinse. By implementing advanced process control technologies into our automated and high-speed equipment, we achieve consistent, edge-to-edge finishes that match your desired physical and mechanical specifications.

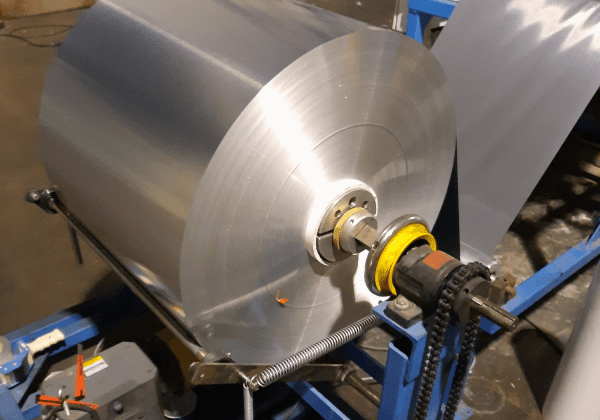

We process aluminum strip measuring from .00075″ to .125″ in thickness and supply it in coils as large as 12.0′ in diameter. Whether you need a quantity as small as a single pound or require massive volumes that range up to a million pounds or more, we have the flexibility to handle your order quickly and accurately. We can supply coil in a natural finish, or you can choose to have it dyed from a standard palette of color choices or a custom color match. We customize the properties of your material regarding insulation resistance, thermal characteristics, dielectric strength, and electrical performance. Our anodic coatings for conductor coils range from .0002″ up to .001″ in thickness, and we perform inductance and resistance testing to ensure products conform to your exact specifications.

Our in-line coil coater can produce black or white foil – a painted aluminum foil used to block light along with aerospace finishes such as BR 127 corrosion inhibitor. For more details about our magnetic coils and coil processing services please see the table below or contact us directly.

Our facility operates 24/7, and we fulfill small orders in as little as three days and larger orders within a 30-day timeframe. In addition to the industrial magnet market, we serve an extensive range of industries that require an exceptional level of quality and repeatable consistency, start-to-finish, batch-to-batch. Contact us today to learn more about our coil processing services or request a quote.