Over 20 years of service, our team at Ano-Mag specializes in continuous coil anodizing of EC Grade 1350 Aluminum strip using Sulfuric Anodization (Type 2, Class 1). We utilize a 135 ft in-line coil anodizing system capable of degreasing, etching, sealing, drying, and recoiling continuous length strip with a maximum outer diameter of 96 in at tolerances of ±.0001 in. Our coil anodizing process is available with standard mill finish or anodized-colored surfaces.

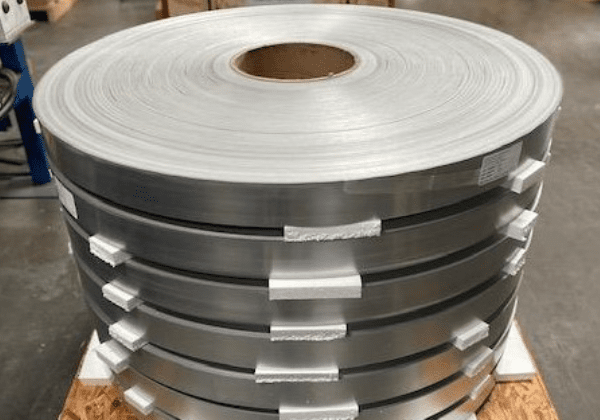

All of our Aluminum strip undergoes in-process testing and inspection using a linear ohms check for each determined length. We perform extensive Isoscopic measurements to ensure accurate anodic coating thicknesses are applied consistently across the entire strip as well as to exact customer specifications. All coil strips undergo winding and banding along with a lead attachment fully taped to the coil’s surface.

We produce volumes ranging from 1 to 1,000,000 lb within a 2 to 4 weeks lead time, supported by worldwide delivery services. ANO-MAG coils eliminate interleave and provide continuous magnetic lifting and separation – as supported by our 10 year limited warranty. To learn more about our continuous coil anodizing services, please contact us directly for more information or for a quote on your next project.